Emptying building materials from Big Bags

IB has developed 7 Big Bag emptying stations to feed additives for producing plaster. The stations are operated by a large German company at their locations in Greece and Tanzania, which is why we focussed especially on robust and low-maintenance operation during the planning stage.

Special features at a glance

- Stable and simple construction

- Low-dust docking for the discharge hose

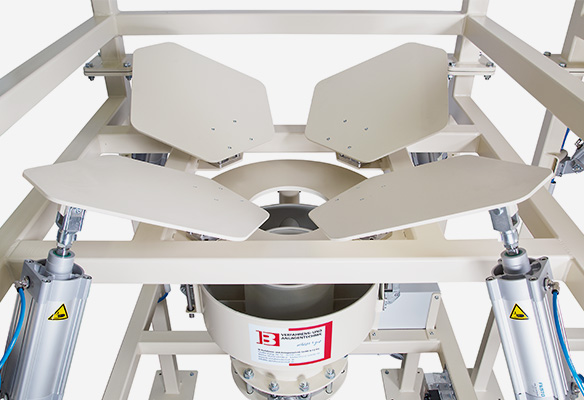

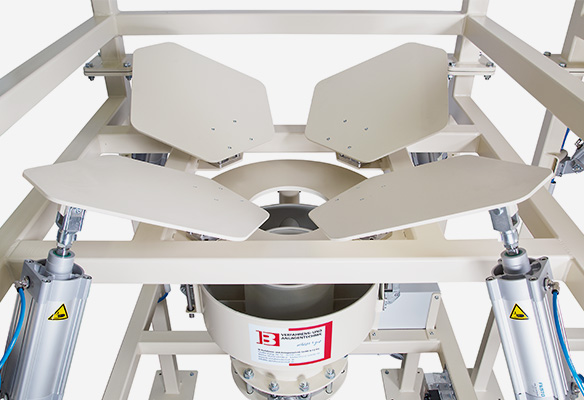

- Milling device for products that flow poorly

- ATEX version for zone: 21/22

- Crane cross members for automatic attachment and detachment

- Cross member with spring re-tensioning to tension Big Bags

- Manual height adjustment for different Big Bag heights

Description

The emptying stations are designed to insert additives into the raw materials mixing process safely and efficiently. The Big Bag loops are attached securely to load hooks on a crane cross member. The cross member is used to insert and set down the Big Bags on the frame using a central ceiling crane.

Due to the dust-explosive products such as cornflour, all interior areas are designed for dust Ex zone 21 and all exterior areas within a metre for zone 22.

The Big Bags are lifted by milling plates in order to support discharge for the raw materials with poor flowing properties and that form bridges. As the weight reduces, the spring re-tensioning system keeps the Big Bags in shape on the cross members. This provides additional discharge optimisation and is used to reduce folds in which product residues may get stuck.