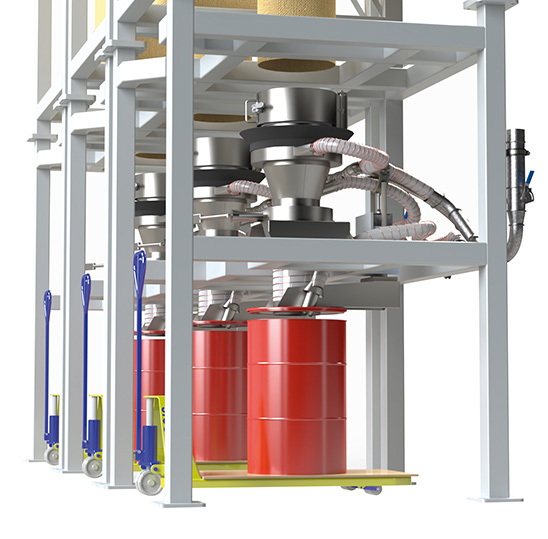

Barrel filling stations

Produce, fill into the barrel and transfer safely to the logistics department: With IB Verfahrens- und Anlagentechnik’s barrel filling system, different container sizes can be filled safely, with low dust and time saving. The solutions tailored individually to the functional and spatial requirements of our customers also adapt flexibly to the capacity of a container. This means that the order quantity is not a question of barrel size.

Facts that will convince you

- Low-dust, safe and contamination-free filling

- Customer-specific filling devices

- Individual interfaces to the previous system

- Insertion and removal on pallet or roller conveyor

- Stainless steel, galvanized steel etc.

- Dedusting

- Various filling systems

- Special solutions

Product description

You can use the barrel filling stations to fill barrels dust-free and efficiently.

Adding a scales enables the barrels to be filled easily and weighed.

The barrel filling system can be designed according to your specific requirements and integrated into existing systems.

Materials

The frames and system components that come into contact with products are made of standard steel 1.0038, stainless steel 1.4301 and from other materials upon customer request.

For the food industry, the system components that come into contact with the products are designed in accordance with Regulation (EC) 1935/2004.

Our individual customer solutions in the container and barrel handling sector

Our systems differ as much as our customers’ requirements and almost always have an individual note. Each system is therefore unique.

We can use system modules to offer, design and produce numerous solutions quickly and in a reproducible manner. Furthermore, our range of modules increases continuously due to the requirements of our new customers.

The references section provides you with a selection of customer projects that have already been completed, along with notable special features.