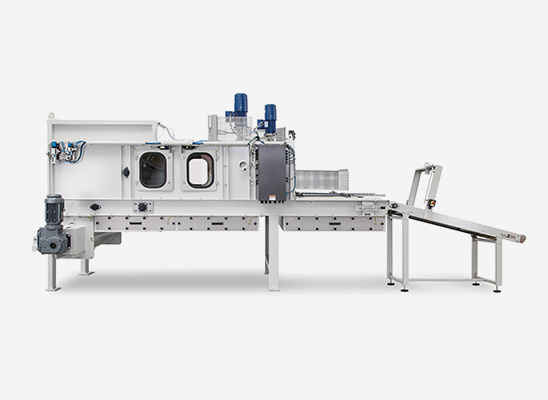

Empty bag compactor

Where does the bag go when it’s empty? If the paper or plastic packaging is compacted according to type, it can be economically disposed of or recycled. The empty bag compactor from IB Verfahrens- und Anlagentechnik ensures that the empty bags quickly run out of air – without whirling up much dust. The sturdy unit consists of a chamber with an overhead mounted screw helix. A power and compressed air connection is sufficient for operation. The empty bag compactor is equipped with rollers for mobile use.

Facts that will convince you

- Protect your employees from hazardous dust

- Reduced waste disposal costs

- Capacity of 5-10 bags

- Low-dust disposal in film tube

- Maximum compaction

- Design in steel and stainless steel

- ATEX version

- Simple and safe operation (plug & play)

- Mobile and stationary version

- Integrated or on-site dedusting

- Rental devices

- Special designs possible

Product description

The empty bag screw compressor can be used to compress paper and plastic bags to around 15 % of the original volume. This reduces the working effort and the disposal costs.

The empty bag compactor comprises a chamber with a single-sided, overhung, heavy-duty screw helix. It is sturdy and easy to use, and can reach all components.

Up to 30 bags can be disposed of in a 2.00 m PE tube section. The tube film has a diameter of around 400 mm, although bag sections with a length of 2 to 3 m have proven themselves in practice.

Materials

Depending on the requirements, the compactors are made of standard steel (1.0038) or stainless steel (1.4301). Other materials can also be used upon customer request.

Safety

A door contact switch switches the rotating screw off immediately when the cover is opened, in order to prevent injuries. Furthermore, there is an emergency stop button on the outside of the housing. An ATEX design for gas and dust is possible.

In order to adhere to low dust emissions in the workplace, the empty bag compactor can be connected to an aspirator provided by the customer or to the jet filter supplied. The filter is fitted directly to the compactor’s platform. Alternatively, a separate filter can be set up next to the empty bag compactor and connected using a connection hose.

Functional description

Attaching a film tube to the empty bag compactor

Seal one side of the empty tube with cable ties. Use a torque bag clamp on the empty bag compactor’s screw outlet to attach the open end of the film tube.

Inserting the bags

The operator fills around 5 to 10 bags into the compactor. The cover is then closed on the mobile variant.

Starting the empty bag compactor

After you press the start button, the screw starts to turn slowly. The bags are therefore pressed into the screw helix that becomes smaller and conveyed towards the film tube. The screw helix compresses the bags by up to 85 %.

Ending the compacting process

After running the compression duct empty, the operator switches the empty bag compactor off. A time-controlled shut-down can be added as an option.

Replacing the film tube

Once the maximum length is reached, the film tube is ties off manually,cut off and sealed using a cable tie. The tube can then be stored intermediately and disposed of. Then connect the new tube section to the empty bag compactor as already described.

Downloads

Our individual customer solutions in the bag handling sector

Our systems differ as much as our customers’ requirements and almost always have an individual note. Each system is therefore unique.

We can use system modules to offer, design and produce numerous solutions quickly and in a reproducible manner. Furthermore, our range of modules increases continuously due to the requirements of our new customers.

The references section provides you with a selection of customer projects that have already been completed, along with notable special features.